The UQ Innovate maker space facility allows students and staff to collaborate, create, assist and give guidance through the progression of your projects.

With access to a purpose-made design and fabrication facility, UQ Innovate is an immersive learning environment with staff who share a variety of relevant industry skills and experience.

If you're not sure where to begin? Read getting started, or our frequently asked questions!

UQ Innovate

The makerspace is an open access workshop available to students and staff of UQ to meet, collaborate and create in a purpose-made design and fabrication facility. The space has 16 workbenches available as well as hand and power tools for mechanical fabrication. This space is also used for practical course support.

Equipment available

- Hand and power tools

- Laser cutter

- 3D printing

- Vinyl cutter

- Waterjet profile cutting

- Milling machines (Manual and CNC)

- Lathes

- Drill press/tapping

- Cutting operations

- Grinding/sanding/polishing

- Sheet guillotine and folders

- Welding

- Industrial robot

- Basic electronics including soldering and test equipment

Browse our equipment and tools.

Workshop operating hours

8:00am–3:30pm, Monday to Friday

Location

Building: Mansergh Shaw Building (45)

Rooms: 131, 132 & 134

Workshop Supervisor

Robert Holler

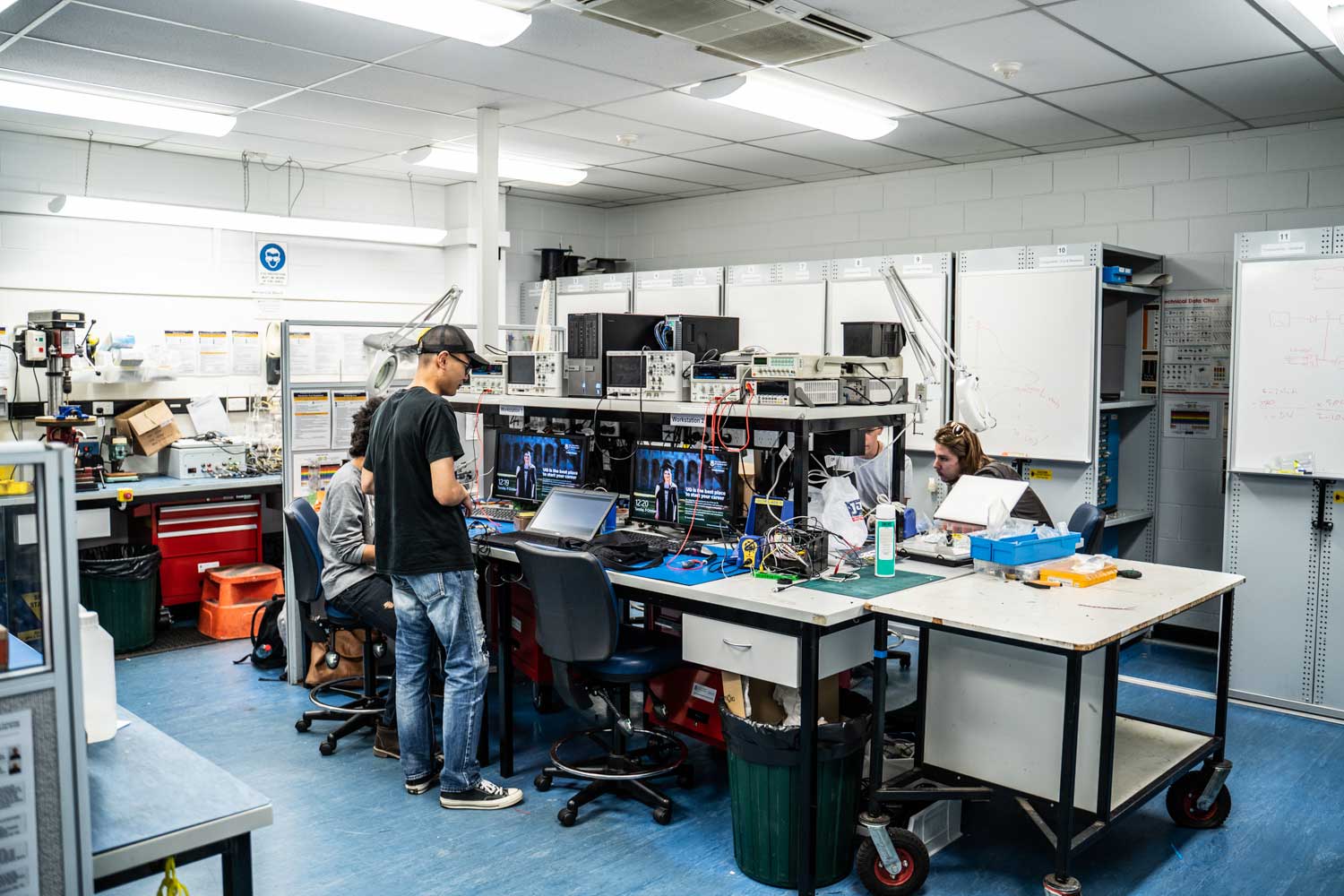

UQ Innovate – Electronics

The Electronics Workshop is available to all staff and students. It is administered by a team of electronic engineers who bring industrial experience directly into a practical teaching environment.

Equipment available

- Electronic design engineering and consulting

- Soldering – Through Hole

- Soldering – Surface Mount

- PCB Re-work

- PCB Design and Manufacture

- Supervisory Control system design and implementation

- Data Acquisition system development

- Instrumentation (sensors and signal conditioning) equipment loan

- Calibration (Temperature, Acceleration, Pressure)

Workshop operating hours

8am–4pm, Monday to Friday

Location

Building: Mansergh Shaw Building (45)

Rooms: 103, 104 & 106

Workshop Supervisor

Malcolm Marker

Advanced Prototyping Workshop (APW)

The Advanced Prototyping Workshop is a professionally staffed mechanical design and machining facility, equipped with the latest CNC equipment. The team is available to assist students and staff in the development of prototypes and fabrication projects, and they can also advise the best way to design and deliver your next project.

*Staff and students wishing to interact with the APW must first:

Equipment available

- Mechanical design engineering (advice or consultation)

- Design For Manufacture (DOM) advice

- Prototypes through to custom builds for research and undergrad Pracs.

- CNC milling (3, 4 and 5 axis)

- CNC turning

- EDM wire cutting

- Waterjet cutting

- Manual machining

- Welding (steel, aluminium, Stainless steel)

Browse our equipment and tools.

Workshop operating hours

7am–3pm, Monday to Friday

Location

Building: Mansergh Shaw Building (45)

Room: 111A

Workshop Supervisor

Jason Herriot

Collaborative Workshop (CoLab)

The Collaborative Workshop (CoLab) provides facilities and equipment for architectural model making and 1:1 scale prototyping. The CoLab also offers a variety of model-making materials available for students to purchase.

The workshop is equipped with a full range of hand tools, woodworking machinery, a flatbed CNC router, and laser cutters. Enrolled students can access information about the CoLab through Blackboard (look for My Organisations > COLAB).

It is a flexible space, designed to adapt to the different stages of the design process. Students are encouraged to use the CoLab as an informal study space where they can test their designs with 3-dimensional forms and get creative.

Find out more about how the Co-Lab works.

UQ Innovate Electrical Workshop

The workshop provides electrical inspection, testing, installation support, and compliance services for researchers and students, ensuring all projects align with Australian Standards and UQ electrical safety requirements.

Services

Design and Build

- Safety Interlock Systems: For hazardous equipment and high-risk environments.

- Motor Control Systems: VFD and PLC-based solutions.

- High-Voltage Safety Controls: Specialised systems for high-voltage power supplies.

- Instrument Integration: Systems for connecting Extra-Low Voltage (ELV) instruments to mains power.

- Smart Peristaltic Dosing: Automated pH and DO control with IoT-enabled remote monitoring.

- Temperature Control Systems: Precision regulation for heating equipment and experimental rigs.

- Custom-Built Rigs: Specialised electrical builds for research and pilot systems.

- Repairs and Maintenance: Electrical repair and testing for laboratory equipment.

- Compliance Services: Pre- and post-purchase compliance auditing for imported equipment.

Operational Details

Hours: 8:00 am - 4:00 pm | Monday - Friday

Location: Advanced Engineering Buillding (49), Room 112

Contact and Supervision

Andrew Lagrosa

Principal Technician, Electrical Compliance and Safety

Electrical Licence: 104075

QTP for UQ Electrical Contractor Licence: 80310

Job Requests: a.lagrosa@uq.edu.au

Staying safe at all times

Your safety is our first priority.

Each workshop and equipment has its own safety procedures that you must adhere to. If the equipment you'd like to use requires training, you must complete the requirements before you are provided access.